How AR Model Makers Choose Materials for Stunning Scale Models

When it comes to crafting precise and eye-catching scale models, the materials used can make or break the final product. Whether it’s an engineering model, a marine model, an industrial model, or an architectural model, the team at AR Model Makers knows that selecting the right materials is key to delivering quality. In this article, we’ll explore the materials commonly used by expert miniature model makers like AR Model Makers, how they enhance different types of models, and why they matter to clients across industries. From house models to complex industrial designs, you’ll discover what goes into creating these miniature masterpieces.

Why Material Choice Matters in Scale Model Making

The foundation of any impressive scale model lies in its materials. At AR Model Makers, every engineering model or marine model is built with purpose, precision, and durability in mind. The right materials ensure that the model not only looks realistic but also withstands handling and time. Whether you’re showcasing a prototype to investors or displaying a house model for a real estate project, material selection impacts both aesthetics and functionality.

Common Materials Used by Miniature Model Makers

Miniature models come in all shapes and sizes, and so do the materials used to create them. Here’s a breakdown of the most popular choices at AR Model Makers and how they’re applied.

Wood – The Timeless Classic

Wood is a staple for architectural models and house models due to its versatility and natural appeal. AR Model Makers often use balsa wood or plywood for lightweight structures and intricate detailing. For example, a house model might feature wooden frames to mimic real-life construction, giving clients a tangible sense of the design.

Acrylic and Plastics – Precision and Durability

For engineering models and industrial models, acrylic and high-quality plastics like ABS or PVC are go-to options. These materials allow best engineering model makers like AR Model Makers to craft durable components that replicate machinery or structural elements with pinpoint accuracy. Transparent acrylic is especially useful for showcasing internal mechanisms.

Metal – Strength for Industrial and Marine Models

When building marine models or heavy-duty industrial models, metals like aluminum or brass add realism and strength. AR Model Makers might use metal for ship hulls or factory equipment, ensuring the model withstands wear while reflecting the robustness of the real thing. This is why they’re considered among the best marine model makers in the industry.

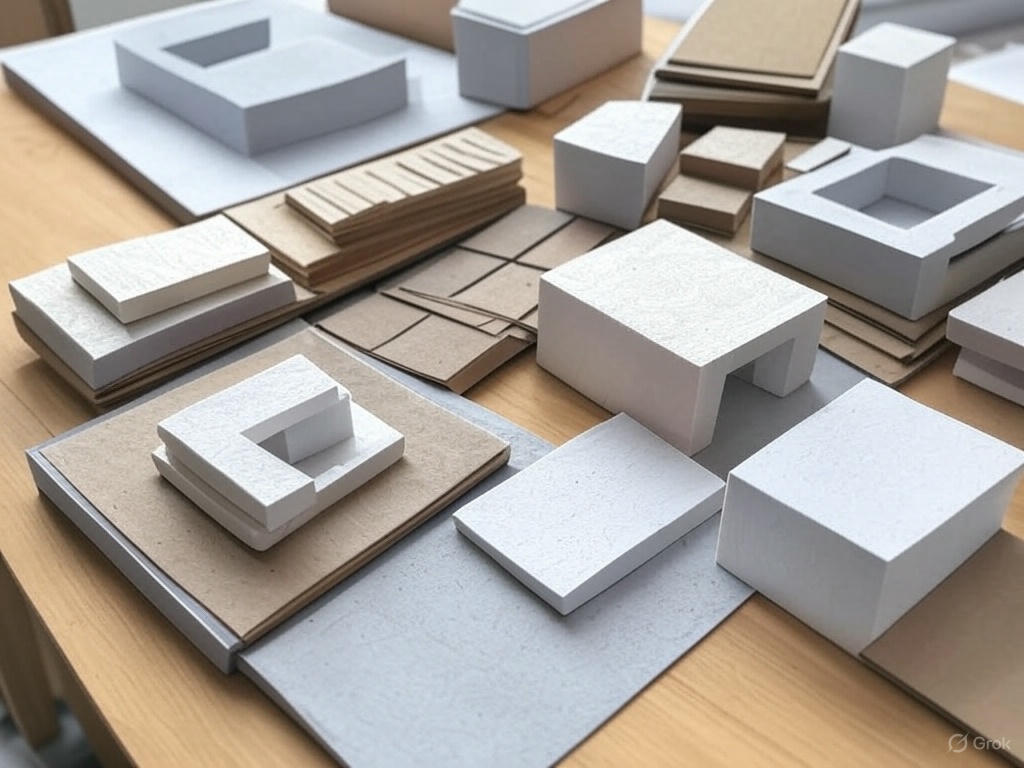

Foam and Cardboard – Lightweight and Cost-Effective

Foam boards and cardboard are often used for quick prototypes or large-scale architectural models. These materials are easy to cut and shape, making them ideal for conceptual designs before moving to more permanent materials. AR Model Makers leverages foam for early-stage house models to test layouts efficiently.

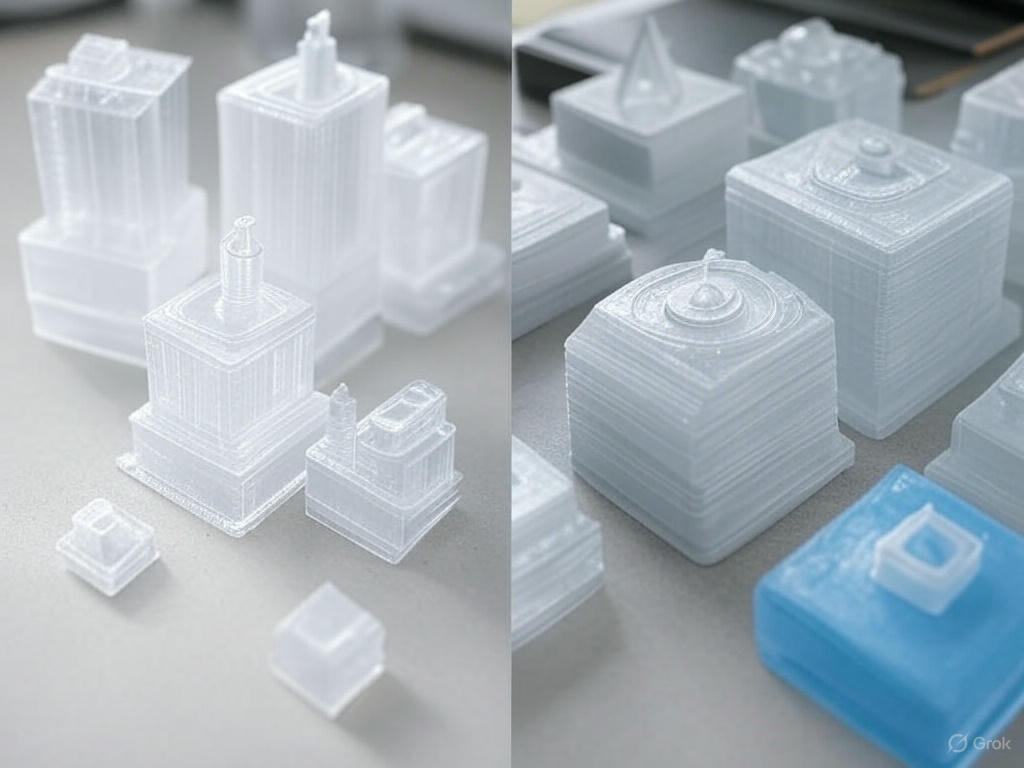

3D Printing Resins – The Future of Model Making

Modern miniature model makers are embracing 3D printing, and AR Model Makers is no exception. Resins used in 3D printing allow for intricate details in engineering models and marine models, offering unmatched precision. This technology is especially popular among top model makers in India for its speed and customization options.

How AR Model Makers Tailor Materials to Your Project

Every project at AR Model Makers is unique, and material choices reflect that. For a marine model, they might combine metal for the hull with acrylic for water effects, creating a lifelike display. An industrial model could blend 3D-printed parts with metal accents to highlight machinery. By understanding the project’s purpose—whether it’s a trade show display or a client presentation—AR Model Makers ensures the materials align with both budget and vision.

For instance, a recent house model project in Delhi used a mix of wood and foam to craft a realistic neighborhood layout, earning praise from clients and establishing AR Model Makers as one of the best model makers in Delhi.

The Role of Craftsmanship in Material Selection

Materials alone don’t tell the full story—expert craftsmanship brings them to life. As one of the best model makers in Mumbai and beyond, AR Model Makers combines cutting-edge tools with hands-on expertise. Their team knows how to sand wood to a perfect finish, weld metal seamlessly, or paint acrylic for a polished look. This dedication elevates every engineering model, marine model, or architectural model they produce.

Interested in the process? Learn more about their approach on the AR Model Makers About Us page.

Why Choose AR Model Makers for Your Next Model?

With a reputation as top model makers in India, AR Model Makers stands out for their material expertise and client-focused approach. Whether you need a detailed marine model for a maritime expo or a sleek industrial model for a product pitch, their use of high-quality materials ensures stunning results. Plus, their presence in cities like Delhi and Mumbai makes them accessible to businesses nationwide.

Ready to start your project? Reach out via the AR Model Makers Contact Us page to discuss your vision.

External Resources for Further Reading

To dive deeper into scale model materials, check out these authoritative sources:

If you have a project In mind just give us a Call

Have a project in mind? Let AR Model Makers bring it to life with the perfect materials! Drop a comment below with your thoughts, share this post with fellow model enthusiasts, or reach out to the team at AR Model Makers Contact Us to get started.

FAQ

What materials are best for an engineering model?

Materials like acrylic, metal, and 3D printing resins are ideal for engineering models due to their precision and durability, as used by best engineering model makers like AR Model Makers.

How long does it take to build a marine model with AR Model Makers?

Depending on complexity, a marine model can take anywhere from a few days to weeks, with AR Model Makers using metals and acrylics for top-quality results.