In today’s fast-paced industrial world, the need for precise, detailed, and functional models is paramount. Whether for presentations, demonstrations, or design validation, industrial models play a crucial role. If you’re searching for an expert industrial model maker, understanding the process behind these models can help you appreciate the craftsmanship and technology involved. At AR Model Makers, we specialize in creating high-quality industrial models that meet the unique needs of our clients.

In today’s fast-paced industrial world, the need for precise, detailed, and functional models is paramount. Whether for presentations, demonstrations, or design validation, industrial models play a crucial role. If you’re searching for an expert industrial model maker, understanding the process behind these models can help you appreciate the craftsmanship and technology involved. At AR Model Makers, we specialize in creating high-quality industrial models that meet the unique needs of our clients.

What is an Industrial Model?

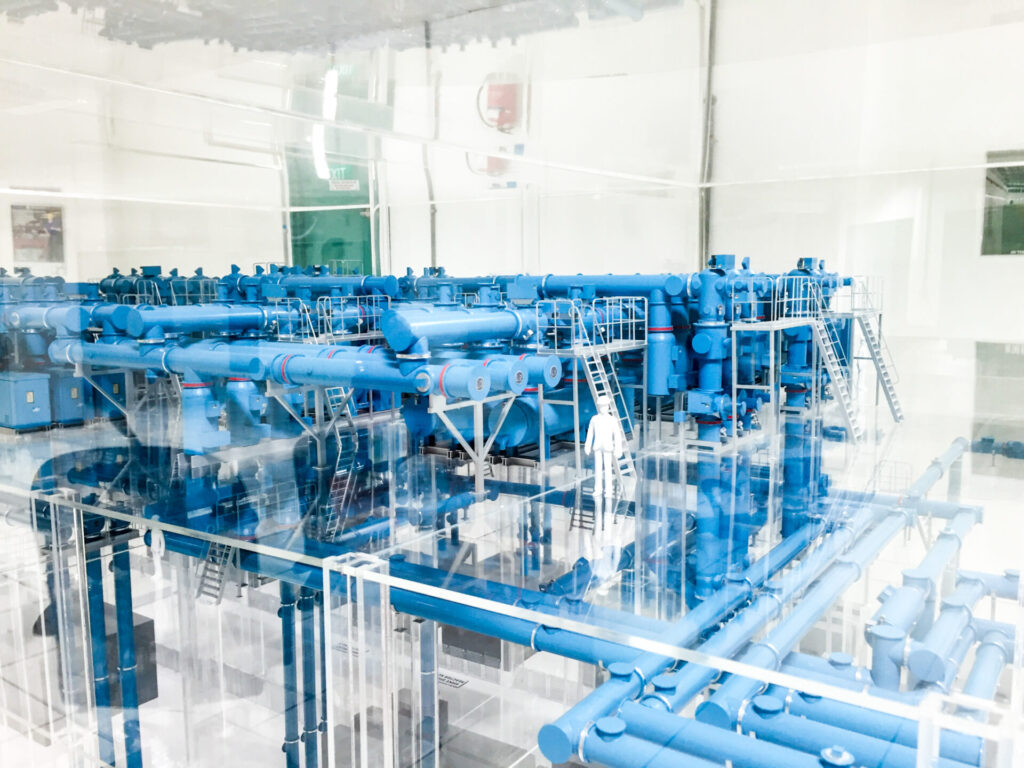

An industrial model is a physical representation of machinery, equipment, or an entire industrial setup. These models are used for various purposes, such as training, marketing, product development, and exhibitions. They help visualize complex designs, making them easier to understand for stakeholders.

The Step-by-Step Process of Creating High-Quality Industrial Models

1. Understanding Client Requirements

The process begins with a detailed discussion with the client to understand their specific needs. This includes:

- Purpose of the model (e.g., demonstration, training, marketing)

- Level of detail required

- Scale and dimensions

- Material preferences

- Budget and timeline

2. Research and Data Collection

After gathering client requirements, our team conducts in-depth research. We collect data such as technical drawings, blueprints, CAD files, and photographs to ensure accuracy in the model.

3. Concept Development and Design

Using the collected data, we develop a conceptual design. Our designers create 3D models using advanced CAD software, allowing clients to visualize the final product before production begins. This step includes:

- 3D modeling and rendering

- Design reviews and feedback loops

- Adjustments based on client input

4. Material Selection

Choosing the right materials is crucial for durability and aesthetics. Depending on the project’s requirements, materials may include:

- Acrylic

- PVC

- Resin

- Metal

- Wood

- 3D printing filaments

5. Fabrication and Assembly

The fabrication process involves cutting, shaping, and assembling the model components. Techniques used include:

- CNC machining

- Laser cutting

- 3D printing

- Hand crafting for intricate details

Once individual parts are ready, they are meticulously assembled to create the final structure.

6. Detailing and Finishing

Attention to detail sets high-quality industrial models apart. This stage includes:

- Painting and surface finishing

- Adding decals, labels, and branding

- Incorporating moving parts if required

7. Quality Control

Before delivery, each model undergoes rigorous quality checks to ensure accuracy, durability, and aesthetic appeal. Our team verifies:

- Dimensional accuracy

- Structural integrity

- Finishing quality

8. Delivery and Installation

Finally, the model is carefully packaged and delivered to the client. If needed, our team also assists with on-site installation and setup.

Why Choose AR Model Makers?

At AR Model Makers, we are committed to excellence in every project. Here’s why we are a preferred choice:

- Expertise in various industrial sectors

- Use of advanced technologies like 3D printing and CNC machining

- Customization to meet specific client needs

- Offices in Delhi and Mumbai for better accessibility

Internal Linking Suggestions

- Architectural Model Makers: Bringing Designs to Life

- The Importance of Scale Models in Product Development

External Links

FAQ

Q1: What materials are best for industrial models?

A: The choice of materials depends on the model’s purpose. Common materials include acrylic, resin, metal, and 3D printing filaments.

Q2: How long does it take to create an industrial model?

A: The timeline varies based on complexity, ranging from a few weeks to a couple of months.

Industrial Models by Expert Industrial Model Makers

High-Quality Industrial Models by Expert Industrial Model Makers

Discover the process of creating high-quality industrial models with AR Model Makers. Expert industrial model makers in Delhi and Mumbai.

Call-to-Action

Ready to bring your industrial concept to life? Contact AR Model Makers today for customized, high-quality industrial models tailored to your needs. Share your thoughts in the comments or explore more of our services on our website!